Maintenance is integral to effective pneumatic tool use. Tools last longer, continue to perform well, and remain dependable for every task, but only when techniques like oiling are regularly employed. Take pneumatic staplers or nailers, for example—these invaluable allies are essential in carpentry, upholstery, and various do-it-yourself (DIY) projects, providing precise and efficient fastening. It's important to remember that proper oiling is not a suggestion but a requirement to ensure your tools remain in the best condition. You can give your pneumatic staplers or nailers the attention they need by learning how to oil them.

The Importance of Oiling Pneumatic Staplers and Nailers

Proper maintenance, including regular oiling, is crucial for the performance and durability of pneumatic staplers and nailers. Oiling reduces wear, prevents overheating, and protects against rust and corrosion. It also ensures maximum power efficiency and consistent driving force, producing a professional finish.

Step-by-Step Guide to Oiling

Step 1: Gather Necessary Tools and Materials

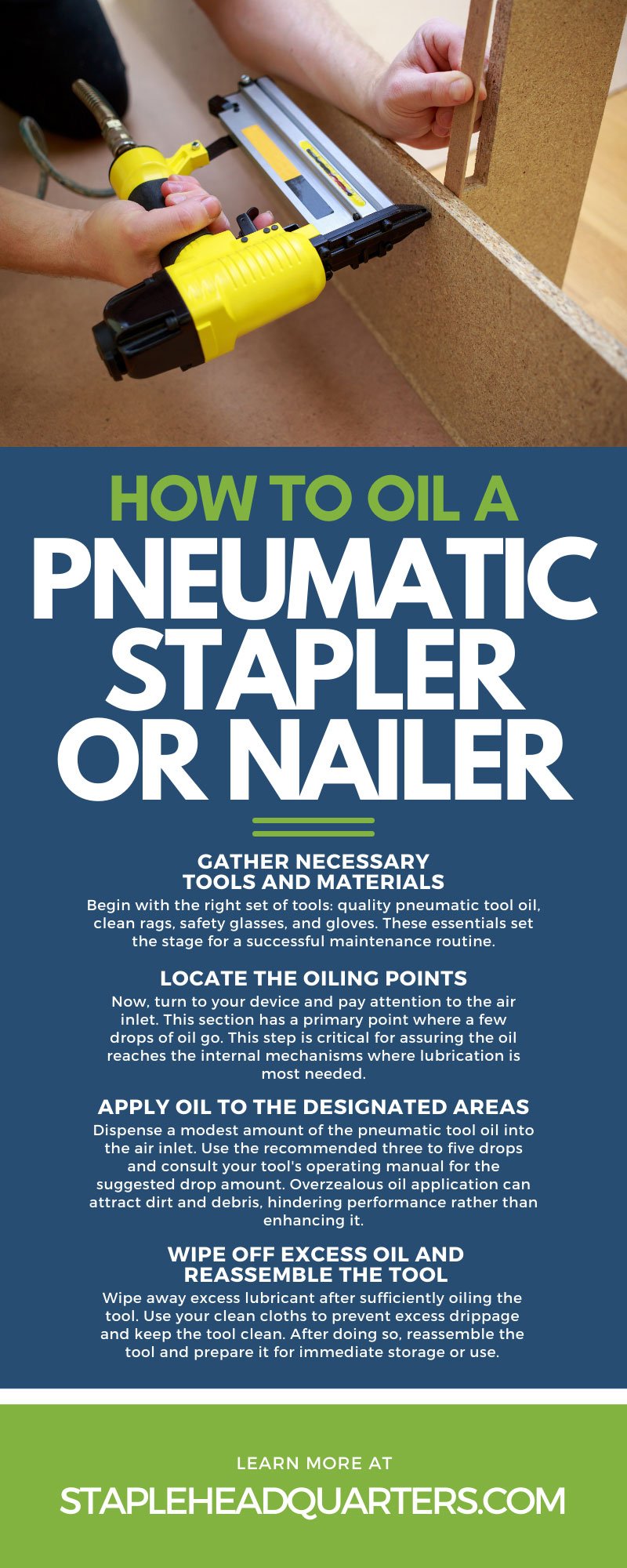

Begin with the right set of tools: quality pneumatic tool oil, clean rags, safety glasses, and gloves. These essentials set the stage for a successful maintenance routine.

Step 2: Locate the Oiling Points

Now, turn to your device and pay attention to the air inlet. This section has a primary point where a few drops of oil go. This step is critical for assuring the oil reaches the internal mechanisms where lubrication is most needed.

Step 3: Apply Oil to the Designated Areas

Dispense a modest amount of the pneumatic tool oil into the air inlet. Use the recommended three to five drops and consult your tool's operating manual for the suggested drop amount. Overzealous oil application can attract dirt and debris, hindering performance rather than enhancing it.

Step 4: Wipe Off Excess Oil and Reassemble the Tool

Wipe away excess lubricant after sufficiently oiling the tool. Use your clean cloths to prevent excess drippage and keep the tool clean. After doing so, reassemble the tool and prepare it for immediate storage or use.

Common Mistakes To Avoid When Oiling Pneumatic Staplers and Nailers

Proper oiling of pneumatic tools is crucial, yet common pitfalls can compromise their efficiency and life span. Awareness and avoidance of these mistakes can markedly improve tool performance and durability.

Mistake 1: Using Incorrect Oil Type

Choosing the incorrect type of oil for a pneumatic stapler or nailer can harm its performance and potentially cause damage. Each pneumatic tool requires specific oil viscosities and properties that protect and lubricate its internal components. Failure to use oil that meets the manufacturer's specified requirements can lead to excess wear and tear, reduce efficiency, and shorten the tool's life span. By not adhering to these specifications, the tool's operation becomes compromised.

Pro Tip

Always use an oil that's designed only for pneumatic tools. Inferior or incorrect oil types can lead to suboptimal performance or even damage. Check the manufacturer's specifications for recommended oil and abide strictly by these guidelines.

Mistake 2: Over-Oiling

Over-oiling a pneumatic stapler or nailer may seem effective, but it can cause complications as damaging as using no oil at all. Excess oil attracts dirt and debris, acting like an abrasive paste that wears down internal components and diminishes the tool's efficiency and life span. Understanding the impact of over-oiling is crucial for maintaining the best condition of your pneumatic tools.

Pro Tip

Apply only the recommended amount of oil. Using more can result in oil buildup that attracts dirt and debris, impeding the tool's function. Adhere to the manual's instructions and resist the urge to over-lubricate.

Mistake 3: Neglecting Regular Maintenance

Regular maintenance is crucial for pneumatic tools. It directly affects their longevity and efficiency. These tools are precision instruments, constantly in motion with internal parts working under high pressure and velocity. Neglecting routine oiling can accelerate wear and tear, leading to potential failures and unscheduled downtime. This oversight then results in repair costs or replacements and the interruption of work. Understanding the impact of maintenance neglect is essential for those relying on pneumatic stapling and nailing tools for their craftsmanship.

Pro Tip

Establish and adhere to a consistent oiling routine so your tool’s moving parts stay well lubricated and work efficiently. Delaying or skipping maintenance sessions can lead to premature wear and potentially costly repairs.

Mistake 4: Allowing Oil To Contaminate Surroundings

When oiling pneumatic staplers and nailers, oil can escape and contaminate a work area or project materials. This problem causes messy situations that potentially damage delicate fabrics, wood, or other surfaces. It is important to be cautious and prevent oil from escaping onto surrounding areas during oiling.

Pro Tip

When oiling the tool, do so in a controlled environment to prevent oil from spilling onto work surfaces or materials. Clean off excess oil with a cloth and properly dispose of it so the workspace stays clean.

Mistake 5: Ignoring Environmental Conditions

Pneumatic staplers and nailers can be quite sensitive to their surrounding environments during use and storage. Humidity and dust levels significantly impact your tool's performance and longevity. Neglecting to consider the ambient conditions can lead to contaminants entering vulnerable areas through your tool's air supply, compromising internal lubrication and potentially damaging the tool and its operations. Stay mindful of these facts to ensure your tool continues to operate well.

Pro Tip

Consider the conditions where your tool will be operating. The two things that can significantly influence oil are extreme temperatures and high humidity. Adjust maintenance procedures accordingly to counteract any adverse environmental effects.

By understanding these common oiling mistakes and implementing the corresponding avoidance tips, users can ensure their pneumatic staplers and nailers continue to perform reliably, extending the lifespan of these essential tools.

Pneumatic Stapler and Nailers at Salco

Each maintenance session invests in the longevity and effectiveness of a pneumatic stapler or nailer. By following a disciplined care routine, you can rely on these tools to continue to aid in crafting, building, and renovating.

Salco offers a comprehensive selection of quality nailers and staplers that embody innovation and durability. Customers can find products that boast robust performance and longevity, including staples, nailers, and essential accessories for their next project.