Woodworking can take a few different forms, whether you want to create practical furniture that will see use, or smaller decorative, visually appealing items. Regardless of what you intend to make, the tools you will need remain the same, and having a beginner’s guide to woodworking tools will allow you to know what you will need and why a specific tool is essential to have in your arsenal.

Make sure you dive into a project with the right tools; otherwise, lacking the correct tools can halt your progress, or substituting other tools can lead to faulty builds.

A Selection of Saws

The tools you may see the most use out of will be the saws; they are primarily designed for cutting and shaping wood pieces safely and with ease. Different saws have a variety of applications, making each one ideal for a specific job.

Circular Saw

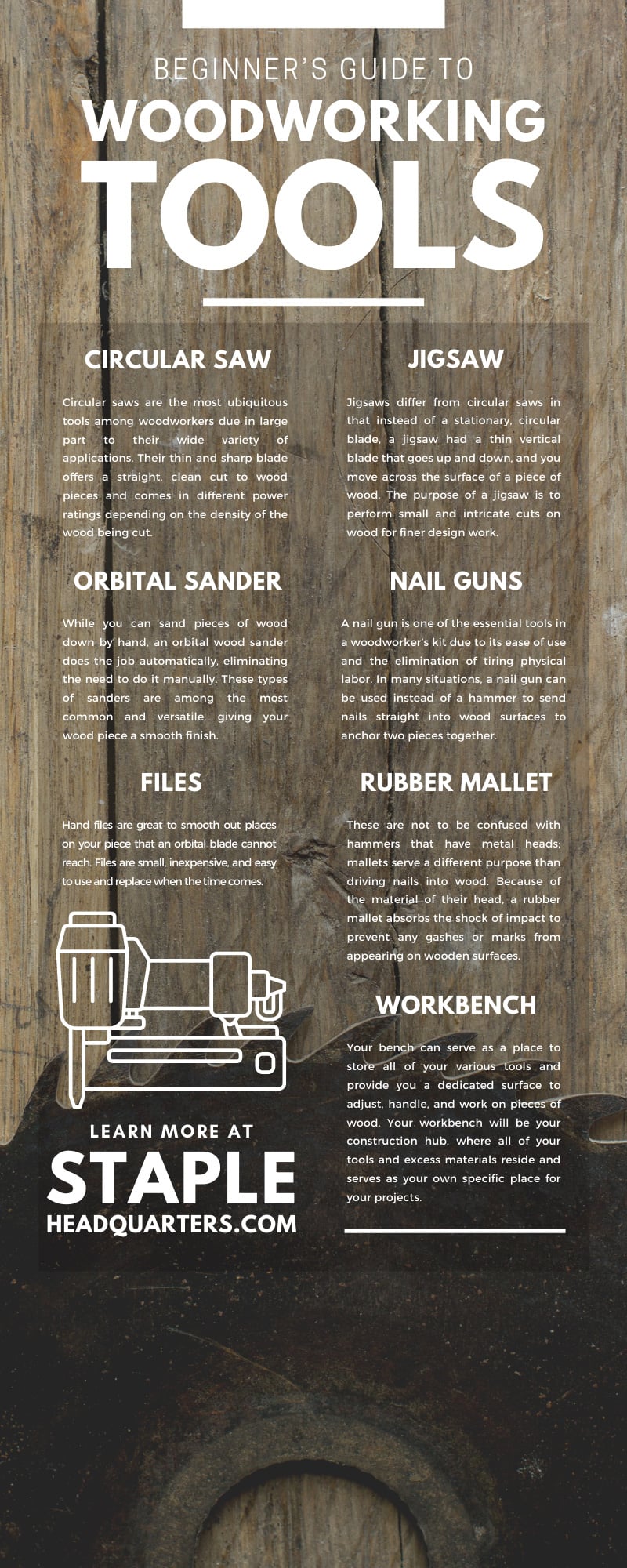

Circular saws are the most ubiquitous tools among woodworkers due in large part to their wide variety of applications. Their thin and sharp blade offers a straight, clean cut to wood pieces and comes in different power ratings depending on the density of the wood being cut.

Two Circular Blade Designs

There are two different designs available to you with circular saws: the direct drive and the worm drive. Typically, a worm drive is designed for more heavy-duty uses, worm drives come with larger gear teeth with more load-carrying capacity than a direct drive, making worm drives more powerful but heavier. Direct drives are the standard saw designs and are less expensive compared to worm drives.

Jigsaw

Jigsaws differ from circular saws in that instead of a stationary, circular blade, a jigsaw had a thin vertical blade that goes up and down, and you move across the surface of a piece of wood. The purpose of a jigsaw is to perform small and intricate cuts on wood for finer design work. These are best applied in specific circumstances that require delicate work, as opposed to quick and straight cuts.

Finishing Wood

Once you cut your wood pieces to the necessary lengths and shapes, you’re going to need to smooth out the rough patches that result from cutting. Finishing your wood not only adds an appealing look to your pieces, but also serves to make the pieces safer to handle by decreasing the risk of splinters or jagged edges.

Orbital Sander

While you can sand pieces of wood down by hand, an orbital wood sander does the job automatically, eliminating the need to do it manually. These types of sanders are among the most common and versatile, giving your wood piece a smooth finish.

Drawback and Alternative

One of the drawbacks of orbital sanders is that they can leave swirl marks on your piece of wood that may be difficult to remove due to their design. A random orbital sander oscillates the blade in random directions that prevent the sander from leaving the swirl marks.

Files

Hand files are great to smooth out places on your piece that an orbital blade cannot reach. Files are small, inexpensive, and easy to use and replace when the time comes. There are several file variants that you should consider:

- Rasp File: These are used for removing large swaths of wood to allow finer files to have an easier time.

- Half-Round File: Ideal to be used on straight or curved surfaces.

- Mill File: Designed to slip into small spaces for precise finishing.

Nail Guns

A nail gun is one of the essential tools in a woodworker’s kit due to its ease of use and the elimination of tiring physical labor. In many situations, a nail gun can be used instead of a hammer to send nails straight into wood surfaces to anchor two pieces together.

Know the Appropriate Uses of a Nail Gun

There are many types of industrial nail guns, and knowing what to use in terms of woodworking is vital to get the best results possible. If you need to adhere two pieces of wood together, using a pneumatic nail gun is ideal. But if you are applying fabric to a wooden structure, you will need an upholstery staple gun for the more delicate work.

Rubber Mallet

These are not to be confused with hammers that have metal heads; mallets serve a different purpose than driving nails into wood. Because of the material of their head, a rubber mallet absorbs the shock of impact to prevent any gashes or marks from appearing on wooden surfaces.

Softer Application

These types of mallets are meant to either hammer two wooden joints into one another or to use in tandem with a chisel to carve designs into wood. Using a metal hammer can create too much force, resulting in your chisel piercing through the wood.

Method of Measurement

Measure twice, cut once, as the saying goes. Also, you won’t be able to get very far without knowing how much material you need to shave off. There are several measuring tools to choose from, and some of the more popular ones include:

- Retractable Measuring Tape: For times when you need to know the length of materials quickly, tape measures typically come in 12 to 30 feet.

- Folding Rules: When you need a high amount of accuracy, you must take your time with folding rules to know the precise measurement of a piece.

- Straight Edges: These are ideal when you need to make quick, straight lines on a piece, so you know where to cut.

Workbench

Finally, you won’t be able to get much accomplished without a workbench. Your bench can serve as a place to store all of your various tools and provide you a dedicated surface to adjust, handle, and work on pieces of wood. Your workbench will be your construction hub, where all of your tools and excess materials reside and serves as your own specific place for your projects.

Invest in Sturdy Design

While you can make your own workbench, you should consider investing in a professionally made bench. This will ensure that it can handle the work you do on it and that it will have the necessary space for all your tools and materials.

Have What You Need

Always make sure to use the correct tools for the job. Using a piece of equipment for purposes it wasn’t built for can lead to early equipment failure. Take care of your tools and only use them for the jobs they were designed to handle; otherwise, woodworking can pan out to be more expensive than you initially expected.