Choosing the right staples can make or break your project. The staples you select affect your work’s durability, appearance, and longevity. Understanding staple types is essential whether you’re a professional contractor or a DIY enthusiast.

Galvanized and stainless-steel staples are among the most popular options available. Each offers unique advantages for specific applications. This comprehensive guide will explore their differences, benefits, and ideal uses. By the end, you’ll be able to choose the perfect staple for your next project.

Understanding Staple Materials

At Salco, Inc., we understand that the material you choose for your upholstery staples is part of the success of your project. Staples come in various materials, but galvanized steel and stainless steel are among the most common. Each material has unique properties that affect performance, durability, and cost.

What Is Galvanized Steel?

Galvanized staples are widely used in construction, crafting, and upholstery. They balance cost and corrosion resistance, making them popular for many applications. This type of steel has a zinc coating. The galvanization process involves dipping steel into molten zinc, forming a protective barrier that shields the steel from corrosion and rust.

The zinc layer in galvanized steel acts as a sacrificial anode. This means that it corrodes instead of the underlying steel when exposed to the elements. As a result, galvanized staples can withstand outdoor conditions better than plain steel staples. However, the zinc coating may wear off over time, especially in harsh environments. The steel underneath becomes susceptible to rust once the coating is compromised.

What Is Stainless Steel?

Stainless steel is a primarily iron alloy with 10.5 percent or more chromium content. The chromium forms a thin layer of oxide on the steel’s surface, known as the passive layer, that prevents surface corrosion and blocks corrosion from spreading into the metal’s internal structure.

Stainless steel staples resist rust naturally without additional coating and are corrosion-resistant, even in harsh environments. They are ideal for projects exposed to moisture, saltwater, or chemicals. Industries such as marine construction, medical equipment, and food processing rely on stainless steel for its hygienic and noncorrosive properties.

These staples maintain their appearance over time, making them suitable for projects where aesthetics is important. While they are more expensive than galvanized staples, their longevity and performance often justify the higher cost.

Key Differences Between Galvanized and Stainless-Steel Staples

Understanding the differences between these staples is essential to choosing the right one. When comparing galvanized and stainless-steel staples, consider factors like strength, corrosion resistance, cost, appearance, and suitability for different environments.

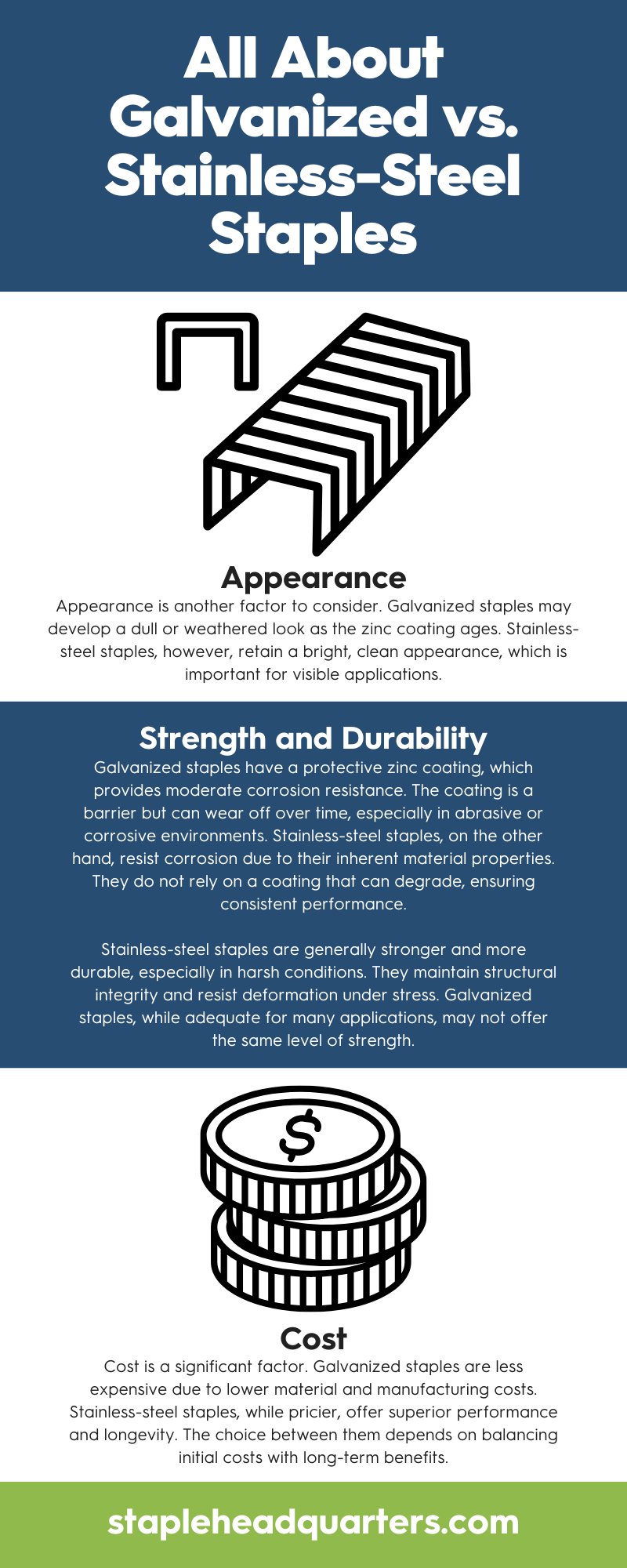

Strength and Durability

Galvanized staples have a protective zinc coating, which provides moderate corrosion resistance. The coating is a barrier but can wear off over time, especially in abrasive or corrosive environments. Stainless-steel staples, on the other hand, resist corrosion due to their inherent material properties. They do not rely on a coating that can degrade, ensuring consistent performance.

Stainless-steel staples are generally stronger and more durable, especially in harsh conditions. They maintain structural integrity and resist deformation under stress. Galvanized staples, while adequate for many applications, may not offer the same level of strength.

Appearance

Appearance is another factor to consider. Galvanized staples may develop a dull or weathered look as the zinc coating ages. Stainless-steel staples, however, retain a bright, clean appearance, which is important for visible applications.

Cost

Cost is a significant factor. Galvanized staples are less expensive due to lower material and manufacturing costs. Stainless-steel staples, while pricier, offer superior performance and longevity. The choice between them depends on balancing initial costs with long-term benefits.

Applications and Uses

Both types of staples excel in specific applications. Choosing between them depends on your project’s requirements and environmental conditions. Consider the environment, expected lifespan, and budget when deciding between galvanized or stainless-steel staples.

Outdoor Projects

For outdoor projects exposed to the elements, stainless-steel staples are the preferred choice. They resist rust and corrosion even in harsh weather conditions, including rain, snow, and high humidity. Projects such as outdoor furniture, decking, and fencing benefit from stainless-steel staples. They ensure structural integrity and maintain a clean appearance over time.

Galvanized staples might suffice in less demanding outdoor environments. They are suitable for temporary structures or projects where some corrosion is acceptable. However, galvanized staples may corrode more rapidly in environments with saltwater exposure or high pollution levels.

Indoor Projects

Both galvanized and stainless-steel staples are suitable for indoor use. In dry indoor environments, galvanized staples perform well and are cost-effective. They are common in framing, furniture assembly, and general carpentry.

If your project is in a humid area or involves exposure to moisture, stainless-steel staples are a better choice. Applications like bathroom fixtures, kitchen cabinets, and areas with high humidity benefit from the corrosion resistance of stainless steel.

Consider the aesthetic aspect as well. Stainless steel staples maintain their appearance without rust stains or discoloration. For projects where appearance is critical, stainless steel provides a cleaner, more professional finish.

Pros and Cons

Evaluating the pros and cons of each type will help you make an informed decision. Understanding the strengths and weaknesses of galvanized and stainless-steel staples allows you to select the best option.

Pros and Cons of Galvanized Staples

Galvanized staples are affordable and readily available, making them a practical choice for many applications. The zinc coating provides decent corrosion resistance, making these staples suitable for various indoor and outdoor projects. Additionally, galvanized staples are easy to work with using standard tools, adding to their versatility and appeal.

However, galvanized staples have limitations. Their lifespan is shorter in harsh or consistently moist environments, as the zinc coating can wear off over time, exposing the steel underneath to rust. While adequate for many applications, they may lack the strength and durability of stainless-steel staples. Furthermore, the coating may leave marks or stains on materials if the coating deteriorates.

Pros and Cons of Stainless-Steel Staples

Stainless-steel staples offer superior durability and corrosion resistance, which are ideal for harsh environments and long-term applications. They maintain their appearance over time without rusting or staining, ensuring a clean, professional look for projects where aesthetics matter. Additionally, they are stronger than galvanized staples and provide better holding power and structural integrity.

On the downside, stainless-steel staples come with a higher cost than galvanized options. They may also be harder to find in some markets or in certain sizes, and their high durability can make them unnecessary for short-term or low-exposure projects. Stainless steel may also add to the complexity of certain jobs due to the harder material; they might require stronger tools or equipment for installation.

At Salco, Inc., we pride ourselves on providing top-quality fastening solutions. Whether you’re working on a small DIY project or a large-scale construction, we have the expertise and products to meet your needs. Contact us today to learn more about our range of staples and how we can assist you.